Committed to Superior Technology

Fluid Logic is the premiere manufacturer of hydraulic valves and systems for high water based (HWCF) and low viscosity hydraulic fluids

About Us

Powerful Leaders in Hydraulic Valve Engineering

Fluid Logic was established in 1994 as a manufacture of Zero Leak Poppet based directional control valves for “Low Viscosity” and “High Water” Based Soluble Oil fluids found regularly in the steel and aluminum industries.

These high water content fluids were used because of their non-combustible nature and safety around hot metal. Special materials and techniques are engineered into our products to handle the erosive nature of low viscosity fluids at high pressures that quickly damage conventional hydraulic spool type valves.

Water Hydraulics

Custom Manifolds

Directional Control

ValvesPilot Valves

Valve Technology

Pipe Testing

Our pipe testing manifolds detects flaws in finished products before use of a user. The use of standard Fluid Logic components made from a combination of salt bath nitriding carbon steel, stainless steels and ceramics, provided a manifold to test pipe strength using the customer’s testing sequence. In testing, the manifold allows the pipe to be filled with raw water or 95/5 fluids and then purging residual air. They follow this by intensifying pressure in the pipe, testing for the ability to handle pressure specified by the customer for specified amount of time using multiple pressure selections. In the event that the pipe is defective, they build in a relief system, maintaining safety at all times. After the test completion, their decompression function safely releases pressure and drains the pipe. Because they take product reliability and safety as seriously as their customers do, they thoroughly test their test manifolds for functionality and pressure accuracy.

Valve Stands

Is one of the leading manufacturers of standard hydraulic valves and systems for high water based and low viscosity fluids. However, we are rapidly gaining attention for their ability to develop custom designs and manage the production of large-scale projects for critical applications. The valve stand featured here required them to incorporate a standard P&T manifold billet and NFPA pattern valves, designing it to meet size restrictions as detailed by the customer. Constructed from salt bath nitriding carbon steel, ceramics and stainless steel, their design offers superior protection against corrosion and failure resulting from high pressure.

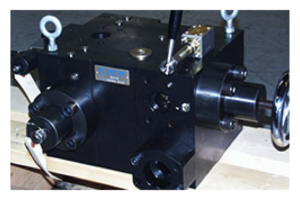

Pump unloading

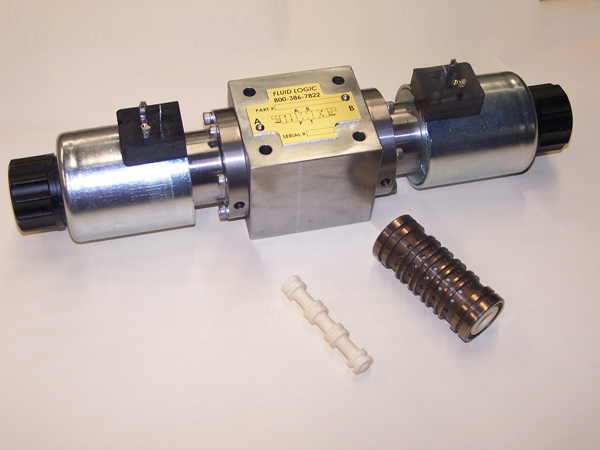

Our pump unloading valve is an example where we take standard sized components and design a customized valve package to save energy. This pump is used by industries requiring a high water based or low viscosity fluids including steel and aluminum mills in addition to oil drilling applications on land and undersea. As a result, we manufacture the valve system to provide many years of service under extreme conditions using salt bath nitriding carbon or stainless steel. While the function of this system is the same, dimensional size varies by the application and customer specifications.

Subsea Valve

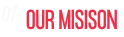

has reputation of manufacturing valve and valve systems that operate in extreme conditions including offshore drilling. Using the latest equipment including high-tolerance grinders and measuring equipment, our skilled workers apply years of technical expertise in ceramic technology machining the subsea valve. We incorporate the use of 316 stainless steel along with proprietary ceramic spools and sleeves and it can withstand 15,000 psi of pressure. Additionally, our design conforms with standard NFPA sizes allowing for compatibility with parts from other manufacturers and operates using raw or salt water in addition to 95/5 fluids. We also provide redundant actuation for the valve using electrical or hydraulics to ensure continuous operation. All subsea valves achieve tolerances of ±.00005″ clearances according to customer specifications and are tested for function and pressure to ensure years of continuous service.

Roll Bending

Our roll bending/roll balance system is unique in the industry due to the manner that they incorporate state-of-the-art electronics into the controls section of the valve assembly. We manufacture the system using 316 stainless steel, which provides material strength to survive pressures of up to 5,000 psi. When combined with electronics, users have the ability to monitor system pressure with a ± 1% degree of accuracy. Furthermore, the system affords customers the ability to use kerosene-based fluids or 95/5 fluids. Because these roll bending/roll balancing systems are custom designed specifically for a customer’s circuit and equipment requirements, they manufacture the system as a make-to-order part.

These valve modules are designed to precisely maintain a system pressure for the critical rolling process of aluminum and steel in both the hot mills and cold mills. State of the art electronics incorporate in controls section of valves Pressures Capability: up to 5,000 psi± 1% accuracy maintainedComplete with on-board electronicsFluid Handling Capability Kerosene Based Fluids 95/5 fluids

Aluminum Billet Caster

This product was designed to control the vertical casting cylinder descent in the process of casting aluminum ingots for future extruding and or rolling operations. Incorporation of standard sized components to develop a customized control manifold package for a specific customers application Designed to accommodate customer’s existing piping schematic Salt Bath Nitriding Carbon Steel, Stainless Steels and Ceramics Includes flow controlled

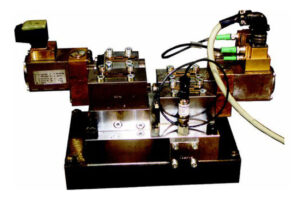

Industries Served

Steel and Primary Metals

Rolling Mill Auxiliary Hydraulics

Descaling Applications

Cast Iron Pipe Industry

Main Pipe Casting Valves

Core Setters

Pipe Pullers

Tire Press Industry

Aluminum Mills

Hot Mill Auxiliary Hydraulics

Cold Mill Finishing

Forging and Extrusions Presses

Mining Industry

Subsea Industry

ROV Systems

Intervention controls

BOP Valves

Oil and Gas Industry

Well Head Controls

BOP Valves

Aerospace

Wind Energy

Military

Valve Technology

Cartridge Assembly Solutions

Fluid Logic Inc. is a recognized producer of mill duty hydraulic valves, offering cartridge assembly solutions for various industrial applications. Our modular construction allows for 2 to 4 way, and dual function and multi-speed configurations. The cartridge systems are composed of 300 and 400 stainless steel, with seats made from durable hardened stainless steel and thermoplastic materials. Soft seats are rated for pressures less than 5,000 psi, and hard seats are applicable for pressures above that amount. Seal materials are abrasion resistant and self-lubricating, and are with incorporated O rings and BU seals. Our flexible cartridge solutions operate by direct solenoid, at pressures from 5,000 psi to 15,000 psi, and handle circuit flows from 10 to 12,000 GPM. Diameters range from DIN 10 (.5") to DIN 300 (12"). Our cartridge solutions are built to accept a range of media, including low viscosity hydraulic fluids, water 95/5, and kerosene based roll coolants, water glycols, high water content fluids, synthetic fluids, inverted emulsions, and mineral oil. All cartridge assemblies are 100% tested, employing pressure, leak, and functional testing methods to ensure the highest accuracy and integrity. Our flexible, high performance standard products are incorporated into systems for reliable and responsive results. For more details about our cartridge assembly solutions or other innovative hydraulic valves and systems please see the table below or contact us directly.

Ceramic & Spool Valve Solutions

Fluid Logic Inc. is an experienced manufacturer of complete ceramic and spool valve solutions, with a number of options and flexible functions to suit demanding requirements. We offer systems featuring 4 way, 2 position and 3 position functionalities, with a choice of actuation devices for valve operation including direct solenoid, hydraulic, air, and manual. Valves are designed with a host of components including spool, sleeve, housing, and coils, along with options such as ATEX coils, proportional valve, proximity switches, and accurate spool position measurement by LVDT. The housing and valve material is a durable stainless steel, with ceramic material composing of the spool and sleeve, and abrasion resistant and self-lubricating O-ring and BU seals. Spool valve diameters are from .25 to .5" (D03 - D05), with match ground diametrical clearances. Our valves withstand pressures ranging from 5,000 to 15,000 psi, handling flow rates of 6 to 20 GPM, and coil voltages from 12V DC to 260V AC. Our ceramic and spool solutions are suitable for a range of industries, particularly the subsea and energy sectors. Customers can expect rapid and repeatable results, along with superior quality standards in compliance with ISO 9001 and NFPA regulations. In addition to our ceramic and spool solutions, we offer a menu of value added services including reverse engineering, complete design services, hydraulic circuits, and on-site installation.

Hydraulic Valve Brochures

Valves for the Water Hydraulics Industry

Custom Engineered Systems

Valve Stands

Ceramic Spool/Sleeve Pilot Valve

Dual Solutions for Descale Service

Proportional Flow Control Valves

Directional Control Valves

Water and Low Viscosity Fluids

Important links

Privacy Policy

Terms of Sale

Terms of Use

Company

Contact

2024 All Rights Reserved © Fluid Logic Valve